|

Resists Gasoline, Solvent Attack

Lubrication and maintenance work often result in spillage of lubricants and fuels on pavements. These dissolve the asphalt paving compounds - - leave dangerous chuckholes - - eventually destroying expensive paving. "Special Purpose" Paving Seal is not harmed by petroleum products. It effectively seals and protects blacktop surfaces - - virtually eliminates destruction due to spillage of gasoline, oil and other types of petroleum products.

"SPECIAL PURPOSE"

PAVING SEAL

Virtually Eliminates Water Penetration

"Special Purpose" Paving Seal forms a protective barrier between asphalt pavement and rain, snow or frost. Alternate rain and sunlight exposure has a destruction effect on asphalt - - ultimately penetrates and breaks it down. Such damage is accelerated in cold weather by freezing and thawing. Hairline cracks soon appear - - chuckholes develop. "Special Purpose" Paving Seal helps prevent water penetration of the sealed surface, thus stopping frost damage in freezing weather - - adds years of life to your asphalt paving.

"SPECIAL PURPOSE"

PAVING SEAL

Gives Maximum Protection

TRC's "Special Purpose" Paving Seal is a rubberized, coal tar emulsion for bituminous surfaces which are exposed to petroleum fuels and oils, heavy impact vehicles, extreme weather and chemicals used for cleaning and de-icing pavement surface. Upon drying, it forms a uniform black surface which keeps its beauty with maintenance free performances under heavy service conditions.

"SPECIAL PURPOSE"

PAVING SEAL

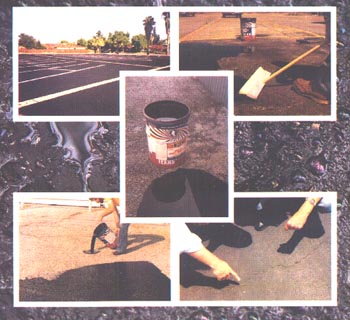

Ready To Use - Quick Drying

"Special Purpose" Paving Seal is ready to use - - easy to apply. Requires no thinner. Just stir or otherwise agitate it in the container until it reaches uniform consistency. It spreads easily. Needs no heat. Surface dries, ready for use, in three to four hours. Do not open area to traffic until Paving Seal is thoroughly dry.

"SPECIAL PURPOSE"

PAVING SEAL

Seals Open Textured Pavements

A slurry composed of "Special Purpose" Paving Seal and clean, coarse sand is advisable for open-texture pavements and inclined surfaces. It fills voids in the subsurface. Gives better traction. Wears better. This slurry is prepared by mixing three to six pounds of sand with each gallon of Paving Seal. One gallon of slurry covers approximately six to seven square yards.

"SPECIAL PURPOSE"

PAVING SEAL

Protects New Black-Top Surfaces

Early protection of black-top surfaces saves expensive repairs. It's only a matter of time until new asphalt paving begins to deteriorate from exposure to rain, snow, or frost. When exposed to spillage of petroleum products, the asphalt paving compounds are quickly dissolved. Protect and preserve the investment in expensive asphalt paving with "Special Purpose" Paving Seal as soon as it is cured. (Cold laid asphalt pavement should cure a minimum of three months.)

"SPECIAL PURPOSE"

PAVING SEAL

Easy Application Instructions

Coverage . . .

One gallon of "SPECIAL PURPOSE" PAVING SEAL covers approximately 60 to 80 square feet. Coverage depends on texture and porosity of surface being sealed.

Preparing The Surface . . .

Remove all dust and loose dirt and other foreign matter. Repair any soft or damaged spots in area to be sealed. Breaks larger than hairline cracks should be repaired with the proper patching materials (TRC POURABLE CRACK FILLER and/or TRC CHUCK-HOLE PATCHING MATERIAL). Pavement must be stable. Use detergent to remove oil or fuel drippings.

Mixing . . .

(Sealer Must Be Agitated)

Just before applying "SPECIAL PURPOSE" PAVING SEAL, stir or otherwise agitate it in the drum or container. Do this thoroughly, until Sealer reaches a uniform "creamy" consistency.

Application . . .

Use "SPECIAL PURPOSE" PAVING SEAL as it comes from the drum. For best results, dampen the pavement with water, making sure there is no puddling. Over a small area at a time, pour on PAVING SEAL at estimated coverage rate and spread it evenly, using a squeegee or brush. Place applicator along edge of pavement. Pull seal toward you along the pavement, parallel to the edge line. Use a brush to remove any puddles of seal.

Important . . .

Do not apply when rain threatens or when temperature is expected to drop below 45? Fahrenheit (7?C.) before Sealer is dry.

|